灌裝範圍 | 0.5L-6000mL |

灌裝精度 | ±5g(4L) |

空氣壓力 | 0.4—0.6Mpa |

耗氣量 | 0.3m³/min |

motor capacity | 1kW |

Size of bottles | Round bottleφ35-φ120mm |

supply voltage | 380V/220V 50/60Hz |

Machine dimensions | 3000mm X1270mm X 2450mm |

<1> Production: 5L of packaging≤ 1400 bottles / hour.

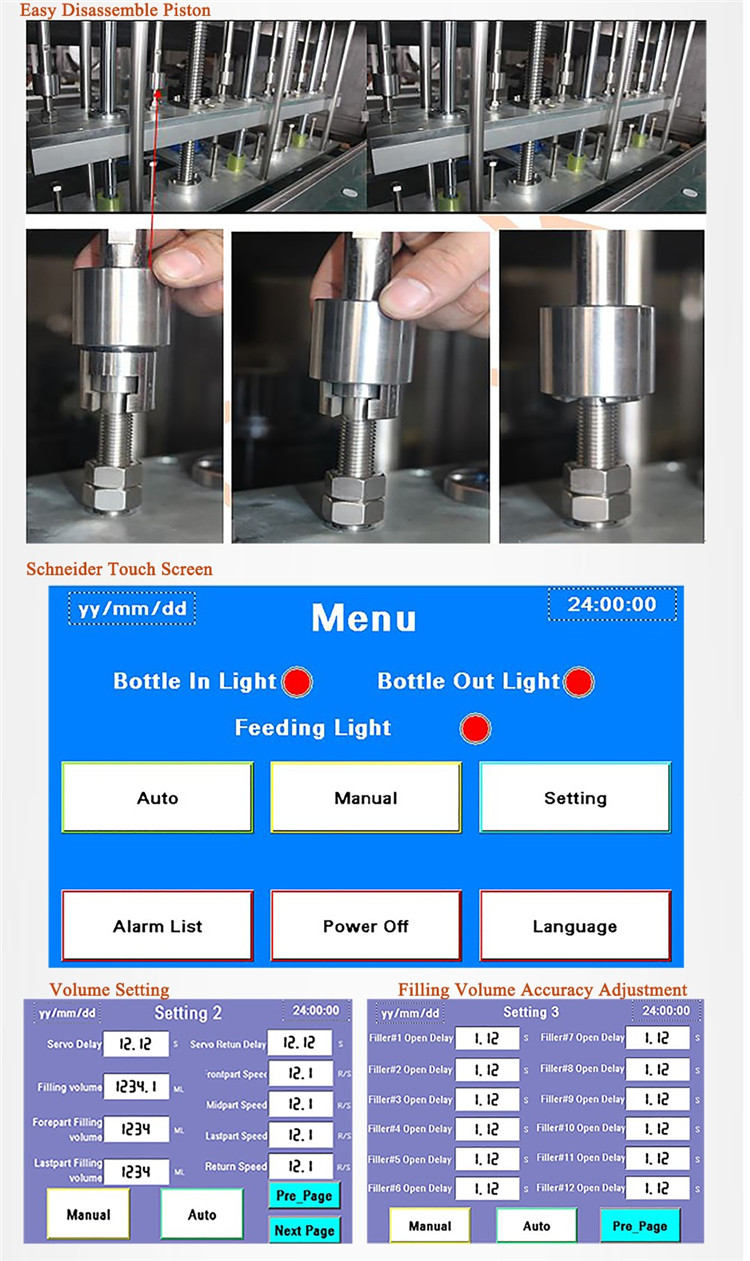

<2> Configuration: Italy Dinacho weighing system, AVIC weighing module, GermanySchneider PLC, Schneider smart touch screen, Schneider low-voltage control, Japan Keyence electric eye, Taiwan Yade passenger pneumatic components.

<3> Each pipe connection point is installed with a quick connector, which is convenient and quick to clean and replace parts.

<4> The anti-drip and anti-drawing back suction filling nozzle ensures that the oil is not drawn and dripped. The whole machine is equipped with a cleaning function, and a special cleaning tank is provided at random, which makes it more time-saving to change products.

<5> Schneider microcomputer PLC control, Schneider intelligent touch screen, change specifications, filling volume adjustment, parameter setting, automatic cleaning, manual operation, etc. are evenly completed on the touch screen. The self-developed floating ball optoelectronic feeding system not only ensures the automatic feeding function in the filling process, but also solves the problem of frequent feeding errors in the filling machine industry.

常問問題

<1>如何確保獲得高質量的機器?

作為製造工廠,我們尋求長期合作,而不是一次性業務,我們對從原材料採購,品牌選擇到零件加工,組裝和測試的每個製造步驟都有嚴格的監督和控制。測試完機器操作的整個過程,直到一切正常為止,然後我們將貨物發送給客戶。

<2>保修和“質量保證”如何?

對於由於我們的設計,製造和材料質量所引起的問題,我們提供12個月的維護期,如果問題是由於上述原因而導致的,則在首次交付時免費提供相關零件和有效的服務。我們將為客戶提供終身技術支持。

<3>安裝和調整如何?

設備到達客戶現場後,負責根據配置圖或在我們的安裝調整技術人員的指導下負責拆箱和佈置設備的客戶。隨機器一起發送的操作手冊和視頻演示說明。我們有中英文操作觸摸屏。此外,我們有專業的售後團隊到客戶現場解決任何問題。最後確定我們的員工費用。

<4>我可以拿些機器的備件嗎?

我們將與包裝在一起的貨物一起發送額外的備件和附件(例如傳感器,電機,墊圈,工具,管道等)。非人為損壞的備件將在1年保修期內免費發送並免費送貨。

<5>是否有針對客戶的培訓?

我們負責為用戶提供技術培訓。培訓內容包括設備的結構和維護,設備的控制和操作。通過培訓,用戶的技術人員可以熟練掌握操作和維護技能,並及時處理一般故障。我們將任命合格的技術人員進行指導。

<6>我們可以定制生產線和機械嗎?

We can customize base on the factory size of our customers’ needs base on the volume of production. You could let us know your factory size drawing; we can do production & machinery design, tank and pipeline welding construction, automatic central control blending system, automatic heating system, filtration system, automatic filling system, automatic three-dimensional storage system, automatic anti-counterfeiting traceability system